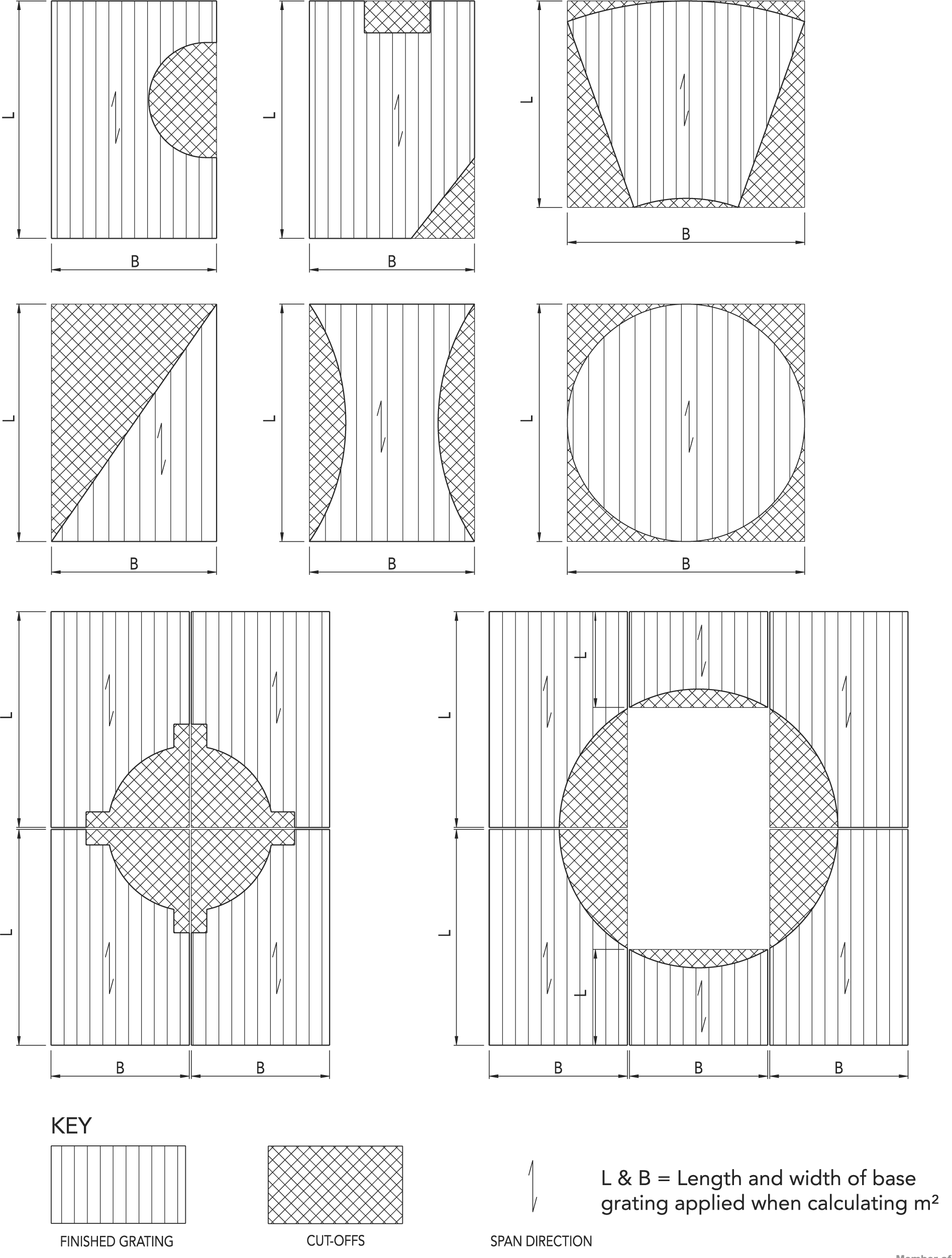

General arrangement of planking

Cutouts

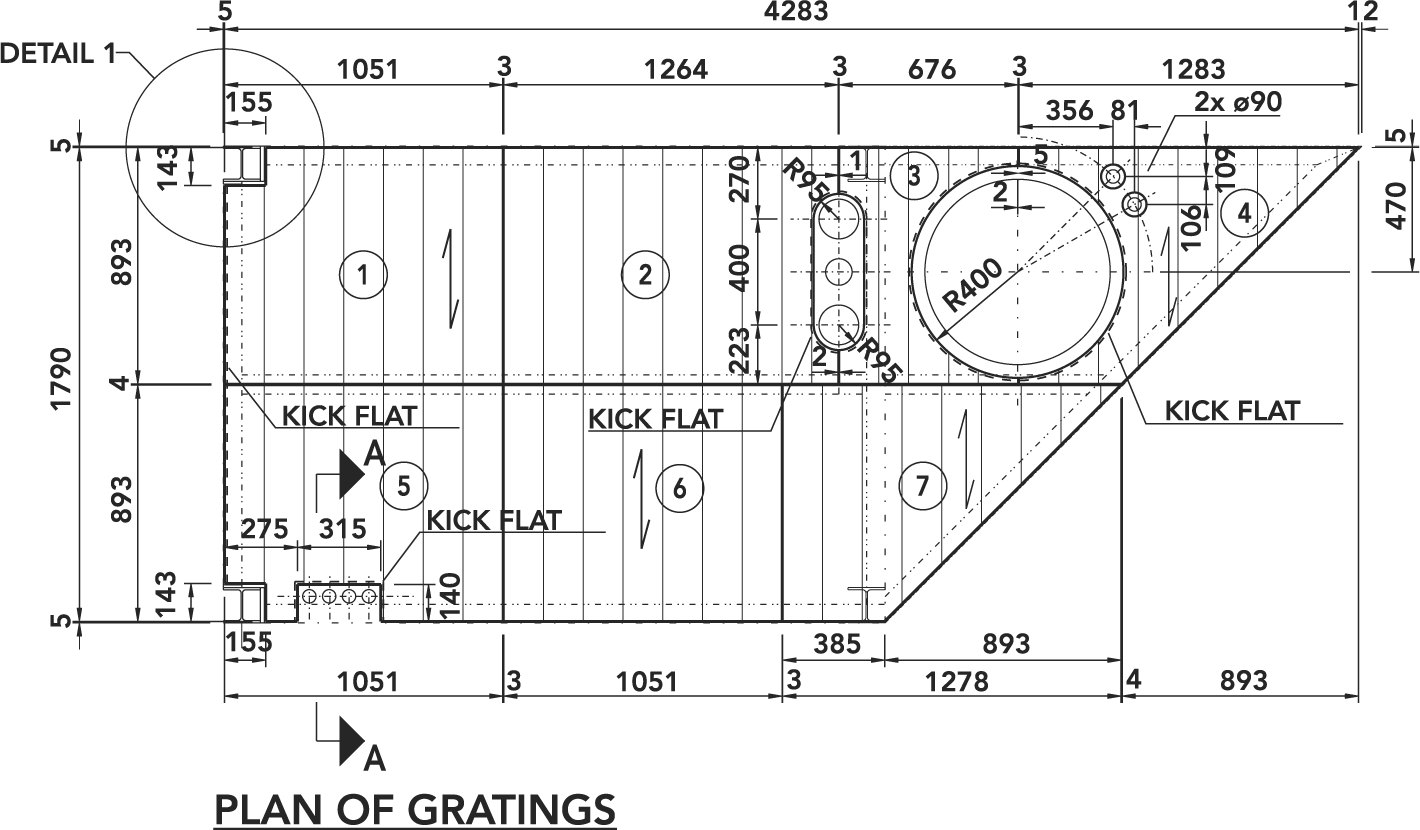

Generally, modules are centrally divided around cutouts in the middle of the module to enable fitting/replacement after the building has been finished.

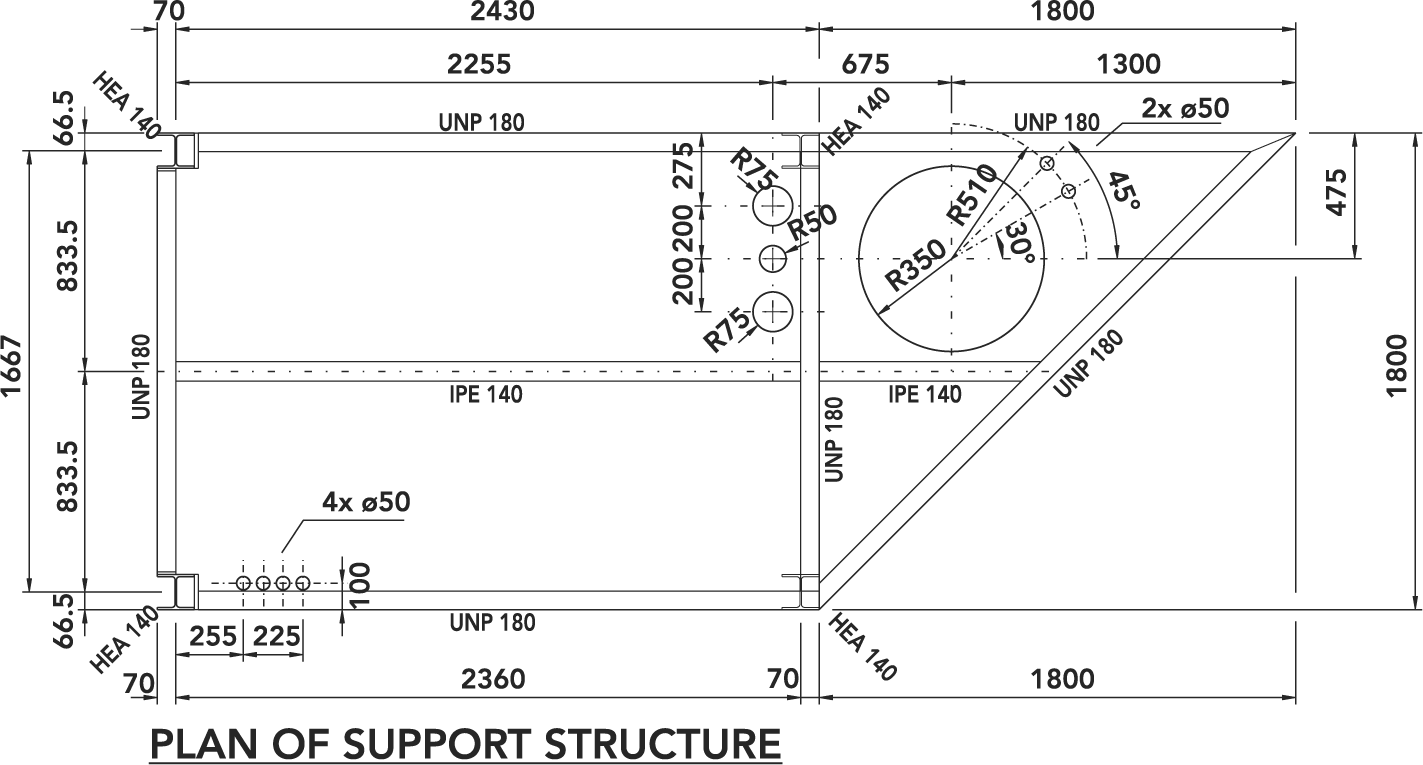

On large or special cutouts it may be necessary to reinforce the module or add an intermediate support in the construction under the panel.

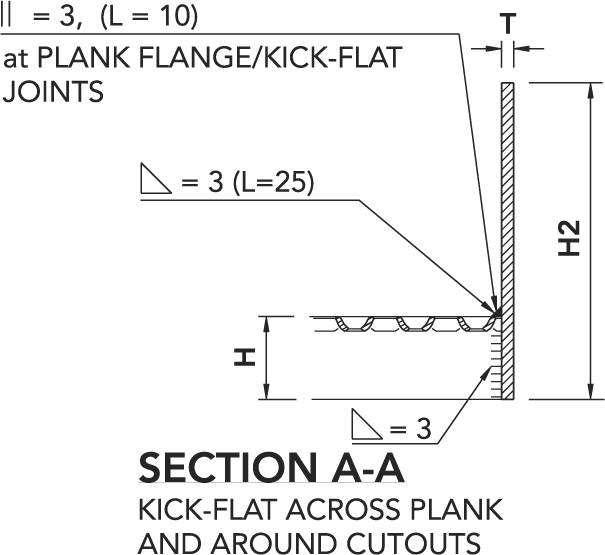

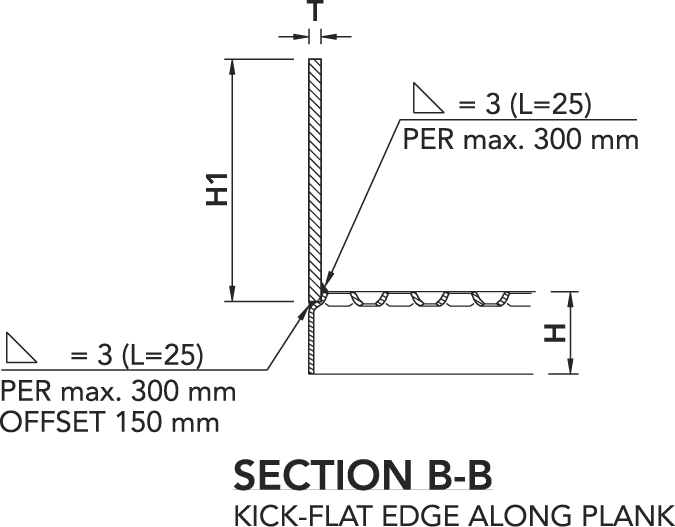

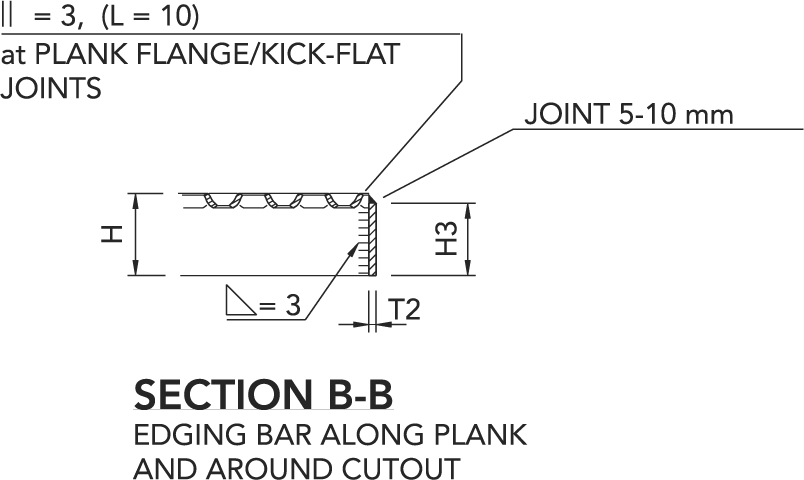

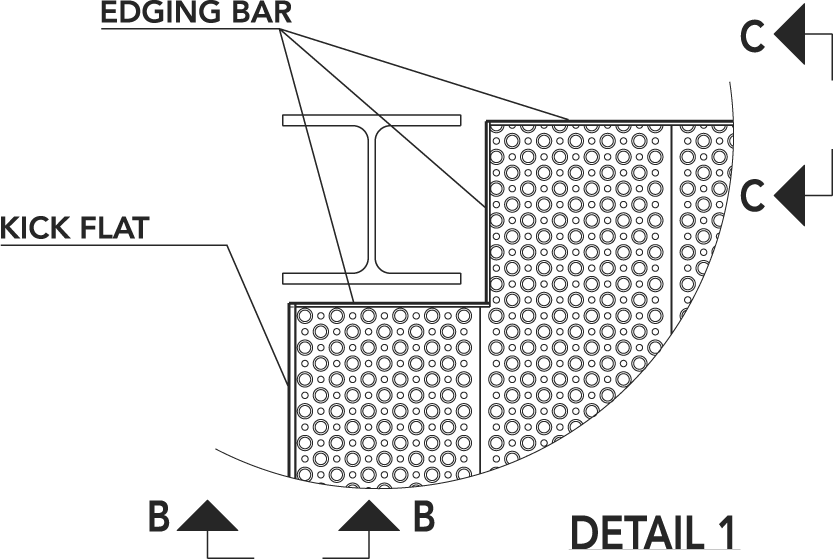

The modules may be supplied with kick-flat in cutouts and/or along the sides.

Generally all cutouts are supplied with a welded-on flat bar, with a min. height of the grating height.

Plank modules

Elefant plank modules are divided into sizes as described in previous section. We endeavour to utilise planks of the same width in each module. However as not all areas lend themselves to an equally divisible dimension; we use "filler planks" in order to maintain required dimensions.

Approx. 3 mm gap in both directions should be permitted when arranging modules; to allow for dimensional tolerances. We recommend modules have a bearing of min. 30 mm.

The panels must be fully supported along both ends, the span direction is marked on the drawing.

All panels/modules are marked with pos. no. panels that are exactly identical (size cutouts, kick-flat, ect) are marked wth the same number.

Calculation of areas

The examples below show the areas to be included when calculating the number of m2 of panel modules with cutouts.