Serrated bars

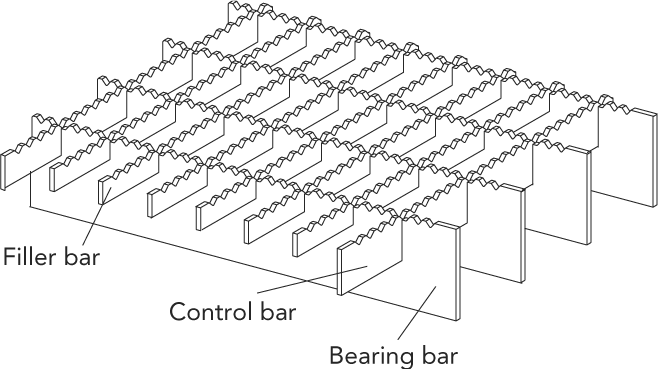

Serrated bearing bars, control and filler bars

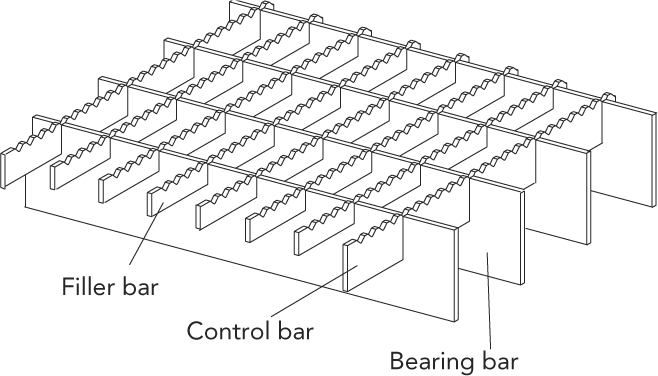

Serrated contol and filler bars

General:

When the gratings are used in particularly wet environments or in places where extra non-slip properties are required, serrated bars will be an advantage.

The serrating process involves punching a pattern in the bars to be serrated (see figures below). This could be in one or both directions. or even specific bars!

Serration is available in two patterns: small serration and large serration

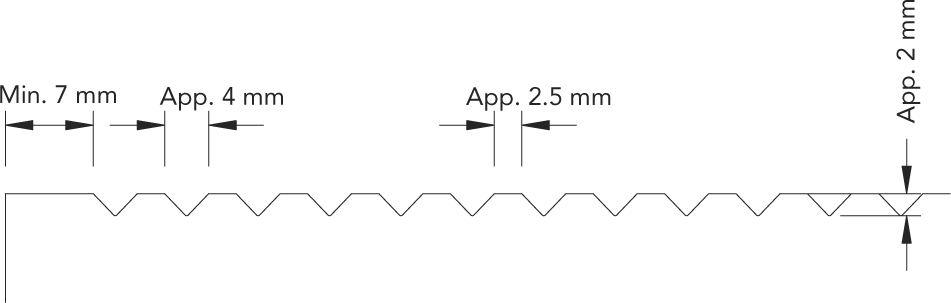

Small serration:

Small serration is the most commonly used serrating type, which is used for industrial walkways and staircases etc. and for heavy duty ramp gratings.

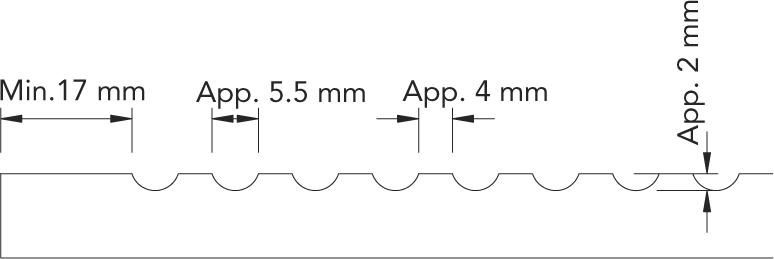

Large serration:

This type of serration is very easy to clean and therefore primarily used in industrial kitchens, canteens and in other places where hygiene and high non-slip requirements are paramount.